Manufacturing Facility

Vacuum oven

Vacuum Furnace for die attach in inert atmosphere. Vacuum oven enables stable solder joints. Desktop robot for precise junction protection and sealant application.

Vacuum oven

Vacuum Furnace for die attach in inert atmosphere. Vacuum oven enables stable solder joints. Desktop robot for precise junction protection and sealant application.

Pad-printing machine

Pad-printing machine for marking.

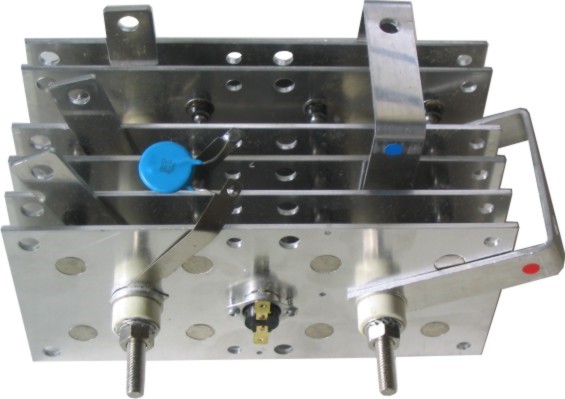

Hydro-Pneumatic press

Hydro-Pneumatic press for mechanical operations.

Testing Facility

Testing facility which includes High Voltage testers, Forward current testers, high temperature voltage testing, Thyristor parameter testing and transistor parameter testing. For Isolated semiconductor modules Isolation Tester, High voltage and High current load tester. For defense customers we are equipped with MIL standard testing which includes- Burn-in test, HTRB, gross leak ,storage life test and rotation test. Traceability is maintained using batch codes or type numbers

MIL Testing

- Stabilization bake- 72 hours @150oC

- Temperature cycling(outsourced)- 10 cycles each of -65oC and +150oC for 10 min.

- Fine leak test-Helium Leak test leak (outsourced)- <5×10-8 atm cc/sec

- High temperature reverse bias- 48 hours at 150oC

- Power Burn-in – 96hours at room temperature.

- Rotation test (outsourced)- – 10000 rpm